Product application:

ZS Stainless Steel Horizontal single-stage centrifugal pump is a kind of multifunctional product with wide application range. It can transport various media including water or industrial liquid, and is suitable for different temperature, flow and pressure range. Its typical applications mainly include the following aspects:

Water supply: filtration, transportation, partition water supply and main pipe pressurization;

Industrial pressurization: process water system, cleaning system;

Industrial liquid transportation: boiler feed water, condensing system, cooling and air conditioning system, machine tool supporting, acid and alkali transportation;

Water treatment: distillation system or separator, swimming pool, etc;

Farmland irrigation, petrochemical, medicine and health, etc.

Installation conditions:

ZS Stainless Steel Horizontal single-stage centrifugal pump is directly connected with pump shaft and consists of pump, pump shaft and standard motor

The pump should be installed in a ventilated and anti freezing place;

The installation of the pump should ensure that the pump is not affected by the tension of the system pipeline;

If the pump is installed outdoors, it must be equipped with a suitable cover to prevent water or condensation of electrical components;

In order to facilitate inspection and maintenance, enough space must be reserved around the unit;

The electric wiring device shall ensure that the pump will not be damaged by phase loss, voltage instability, leakage and overload;

The pump shall be installed horizontally on the base, with the horizontal direction as the suction port and the vertical direction as the discharge port.

Operating conditions:

Clean, thin, non flammable and explosive liquid without solid particles and fibers;

Liquid with temperature between - 20 ℃ and + 100 ℃;

The ambient temperature is higher + 40 ℃;

1000 meters above sea level;

The system has a high pressure of 10 bar.

electric machinery

The motor is fully enclosed, air-cooled two pole standard motor;

Protection grade: IP55;

Insulation class: F;

Standard voltage: 50 Hz 1 × 220 V 3 × 380 V

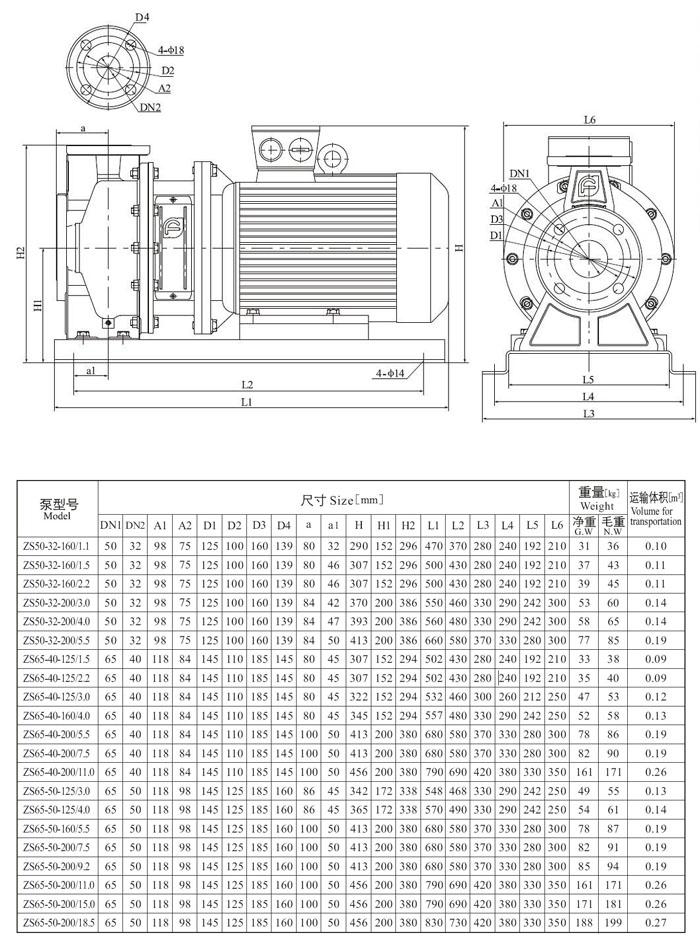

model | lift (m) | flow (m3/h) | Motor power (KW) | speed (r/min) |

ZS50-32-160/1.1 | 18 | 6.3 | 1.1 | 2900 |

ZS50-32-160/1.5 | 20 | 12.5 | 1.5 | 2900 |

ZS50-32-160/2.2 | 25 | 12.5 | 2.2 | 2900 |

ZS50-32-200/3.0 | 32 | 12.5 | 3.0 | 2900 |

ZS50-32-200/4.0 | 42 | 12.5 | 4.0 | 2900 |

ZS50-32-200/5.5 | 54 | 12.5 | 5.5 | 2900 |

ZS65-40-125/1.5 | 13 | 25 | 1.5 | 2900 |

ZS65-40-125/2.2 | 18 | 25 | 2.2 | 2900 |

ZS65-40-125/3.0 | 24 | 25 | 3.0 | 2900 |

ZS65-40-160/4.0 | 28 | 25 | 4.0 | 2900 |

ZS65-40-200/5.5 | 36 | 25 | 5.5 | 2900 |

ZS65-40-200/7.5 | 46 | 25 | 7.5 | 2900 |

ZS65-40-200/11.0 | 62 | 25 | 11.0 | 2950 |

ZS65-50-125/3.0 | 13 | 50 | 3.0 | 2900 |

ZS65-50-125/4.0 | 18 | 50 | 4.0 | 2900 |

ZS65-50-160/5.5 | 25 | 50 | 5.5 | 2900 |

ZS65-50-200/7.5 | 32 | 50 | 7.5 | 2900 |

ZS65-50-200/9.2 | 40 | 50 | 9.2 | 2900 |

ZS65-50-200/11.0 | 48 | 50 | 11.0 | 2950 |

ZS65-50-200/15.0 | 58 | 50 | 15.0 | 2950 |

ZS65-50-200/18.5 | 68 | 50 | 18.5 | 2950 |

ZS80-65-125/5.5 | 13 | 100 | 5.5 | 2900 |

ZS80-65-125/7.5 | 18 | 100 | 7.5 | 2900 |

ZS80-65-125/9.2 | 23 | 100 | 9.2 | 2900 |

ZS80-65-160/11.0 | 27 | 100 | 11 | 2950 |

ZS80-65-160/15.0 | 36 | 100 | 15 | 2950 |

ZS80-65-200/18.5 | 45 | 100 | 18.5 | 2950 |

ZS80-65-200/22.0 | 53 | 100 | 22 | 2950 |

ZS80-65-200/30.0 | 66 | 100 | 30 | 2950 |

ZS100-80-160/11.0 | 15 | 160 | 11 | 2950 |

ZS100-80-160/15.0 | 22 | 160 | 15 | 2950 |

ZS100-80-160/18.5 | 28 | 160 | 18.5 | 2950 |

ZS100-80-200/22.0 | 33 | 160 | 22 | 2950 |

ZS100-80-200/30.0 | 45 | 160 | 30 | 2950 |

ZS100-80-200/37.0 | 54 | 160 | 37 | 2950 |

ZS Stainless Steel Horizontal single-stage centrifugal pump is a kind of multifunctional product with wide application range. It can transport various media including water or industrial liquid, and is suitable for different temperature, flow and pressure range. Its typical application mainly includes the following aspects: water supply: water plant filtration, transportation and partition water supply and main pipe pressurization; industrial pressurization: process water system and cleaning system; industrial liquid transportation: boiler water supply, condensation system, cooling and air conditioning system, machine tool matching, acid-base transportation; water treatment: distillation system or separator, swimming pool, etc; Farmland irrigation, petrochemical, medicine and health, etc. ZS type stainless steel Horizontal single-stage centrifugal pump is directly connected with pump shaft, which is composed of pump, pump shaft and standard motor: 1) the pump shall be installed in a ventilated and anti freezing place; 2) the pump shall be installed to ensure that the pump will not be affected by the tension of the system pipeline during use; 3) if the pump is installed outdoors, it must be equipped with a suitable cover to prevent water or condensation of electrical components; 4) In order to facilitate inspection and maintenance, enough space should be reserved around the unit; 5) the electrical wiring device should ensure that the pump is not damaged by phase loss, voltage instability, leakage and overload; 6) the pump should be installed horizontally on the base, with the horizontal direction as the pump suction port and the vertical direction as the pump discharge port.